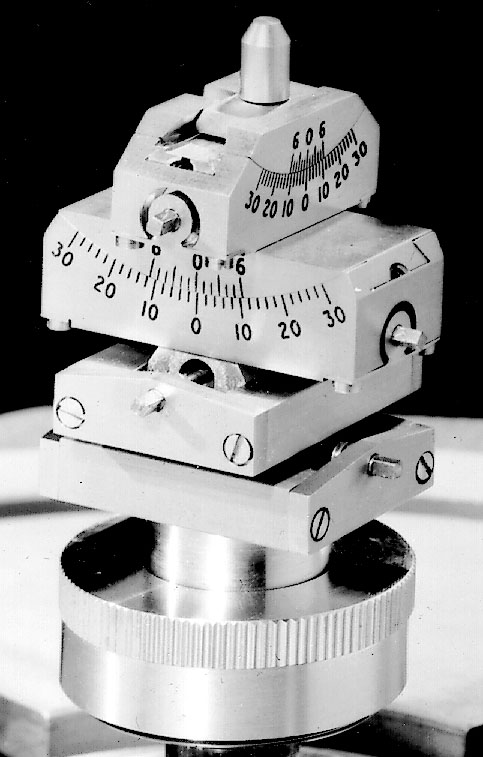

- CSL-U Standard

- Precision Built

- Large Angular Range

- 5-Axis Adjustment

- Centring Slide

- Optionally Motorised

Universal Design

This Goniometer Head is designed to fit on all standard types of optical and X-ray goniometer and diffractometer.

Large Angular Adjustment Range

The main slides are mounted further from the specimen than the arcs, to allow the large angular adjustment range of ± 30°. This is particularly useful for photographic instruments where the crystal axis may require considerable adjustment.

Radial Adjusting Slide

The interchangeable specimen holder can be rotated on its mounting pin, which is carried on a slide allowing 5mm sideways adjustment. Using these two adjustments the crystal can be positioned near to the common centre of the arcs, so as to reduce its off-axis movement during angular adjustment.

Standard Mountings

Three mountings are available: ACA-Standard, in which the base of the head is supported on a short pillar attached to an inverted cup which fits over a spigot on the goniometer, to which it is clamped by a ring-nut: Unicam Geometric, which fits to a plain 3/8" diameter shaft on the goniometer and the Wooster Kinematic mounting which is similar to the ACA-type but replaces the cup with a flange carrying three balls which engage three grooves, ground into a similar flange fixed to the spindle. This avoids the radial plan which is necessarily present in the ACA design. Total reproducibility of position is thus obtained when a crystal is replaced in the diffractometer.

Type CSL-U Standard Goniometer Head

Motorised 5-Axis Goniometer

Stepping motors or DC motors with gear heads can optionally be fitted on some of these goniometer heads.

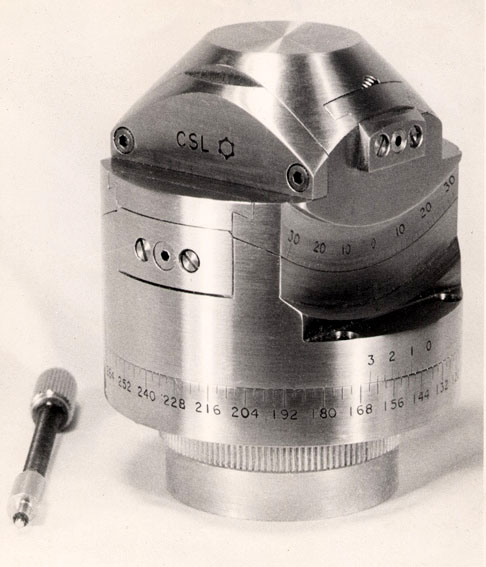

- CSL-WE Standard

- T-Slides for Great Rigidity

- Small Obstructed Angle

- Large Working Distance

- 5-Axis Adjustment

- Lockable

Minimum Obstruction

This Goniometer Head can be used on all standard types of optical and X-ray goniometer and diffractometer. It has been designed to offer the minimum obstruction to rays which are making a small angle with the axis of the head.

Eucentric Design

The straight slides are mounted nearer to the crystal than the arcs, so that provided the crystal is mounted at the correct height above the arcs, and has been brought onto the axis by suitable adjustment of the slides, the angular position of the crystal can be changed without moving it off axis.

Large Working Space

To avoid unwanted scattering, which would otherwise be difficult to exclude from the receiving collimator. The common centre of the arcs is 25mm above the small platform in which the crystal support is mounted. This platform can be rotated through 360° and is divided at 15° intervals. The slides are adjustable through ± 5mm, and the arcs through ± 10°. The vernier gives readings to 5 minutes of arc. When the arcs and slides are in the central position the entire head fits within a cone of semi-angle 15°. All the movements can be made lockable.

Type CSL-WE, Eucentric 5-Axis

Standard Mountings

Three mountings are available:

ACA-Standard. (As illustrated) An inverted cup is attached to the base of the head. This fits over a spigot mounted on the end of the spindle. A radial pin engages with a slot in the edge of the cup to define the mounting angle. A ring-nut clamps the cup to the spigot. Necessary small clearances between the cup, spigot and pin cause a small uncertainty in position when the head is removed and replaced

Unicam Geometric. This fits to a plain 3/8" diameter spindle; providing a four ‘point’ mounting which is clamped by a small thumbscrew. A shake free mounting but without angular positional definition.

Wooster Kinematic. This is similar to the ACA-type but the cup is replaced by a flange carrying three balls, which engage three grooves ground into the spigot attached to the spindle. This kinematic design eliminates the radial and angular play unavoidably present between the cup, pin and spigot of the ACA design. Total reproducibility of position, both angular and radial, is thus obtained when the goniometer head is replaced on the spindle.

- CSL-L3A

- T-Slides for Great Rigidity

- 30° Adjustment Range

- Suitable for Diamond Cutting

- 3-Axis Adjustment

- Lockable

Uses of the Head

This Goniometer Head can be used on standard types of optical and X-ray goniometers and diffractometers. It has been designed to provide a rigid adjustable mounting for the orientation of crystals etc. requiring to be cut at precise angles using diamond-coated saws. T-slides are more rigid than dovetail slides as they separate the necessary running clearances into their two components rather than allowing them to add together.

Working Space

The flat, top surface of the head on which the specimen is mounted is 25mm diameter. The arcs are adjustable through ± 30°. The verniers on the arcs give readings to 5 minutes of arc. When the arcs are in the central position the entire head fits within a cone of semi-angle 45°. The arcs are carried on a turntable which can be rotated through 360° All the movements are lockable.

Standard Mountings

Three standard mountings are available; special mountings can be provided on request:

ACA-Standard. (As illustrated) An inverted cup is attached to the base of the head. This fits over a spigot mounted on the end of the spindle. A radial pin engages with a slot in the edge of the cup to define the mounting angle. A ring-nut clamps the cup to the spigot. Necessary small clearances between the cup, spigot and pin cause a small uncertainty in position when the head is removed and replaced

Unicam Geometric. This fits to a plain 3/8" diameter spindle; providing a four ‘point’ mounting which is clamped by a small thumbscrew. A shake free mounting but without angular positional definition.

Wooster Kinematic. This is similar to the ACA-type but a flange carrying three balls, which engage three grooves ground into the spigot attached to the spindle, replaces the cup. This kinematic design eliminates the radial and angular play unavoidably present between the cup, pin and spigot of the ACA design. Total reproducibility of position, both angular and radial, is thus obtained when the goniometer head is replaced on the spindle.